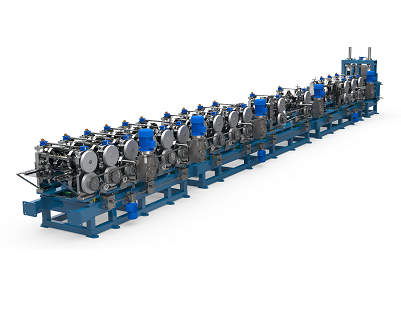

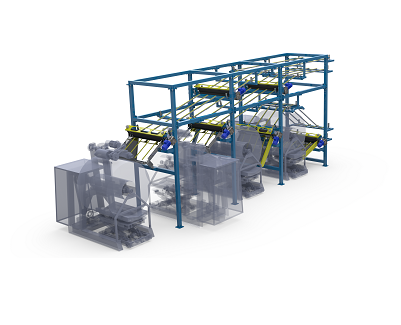

Since 2019, Fabrit has been providing long-term engineering support to a sheet metal machinery manufacturer. The cooperation focuses on the development of new machine designs as well as the improvement and modernization of existing equipment within the client’s product portfolio.

Our role is to deliver complete, production-ready engineering documentation, based on which the client manufactures the machines in-house.