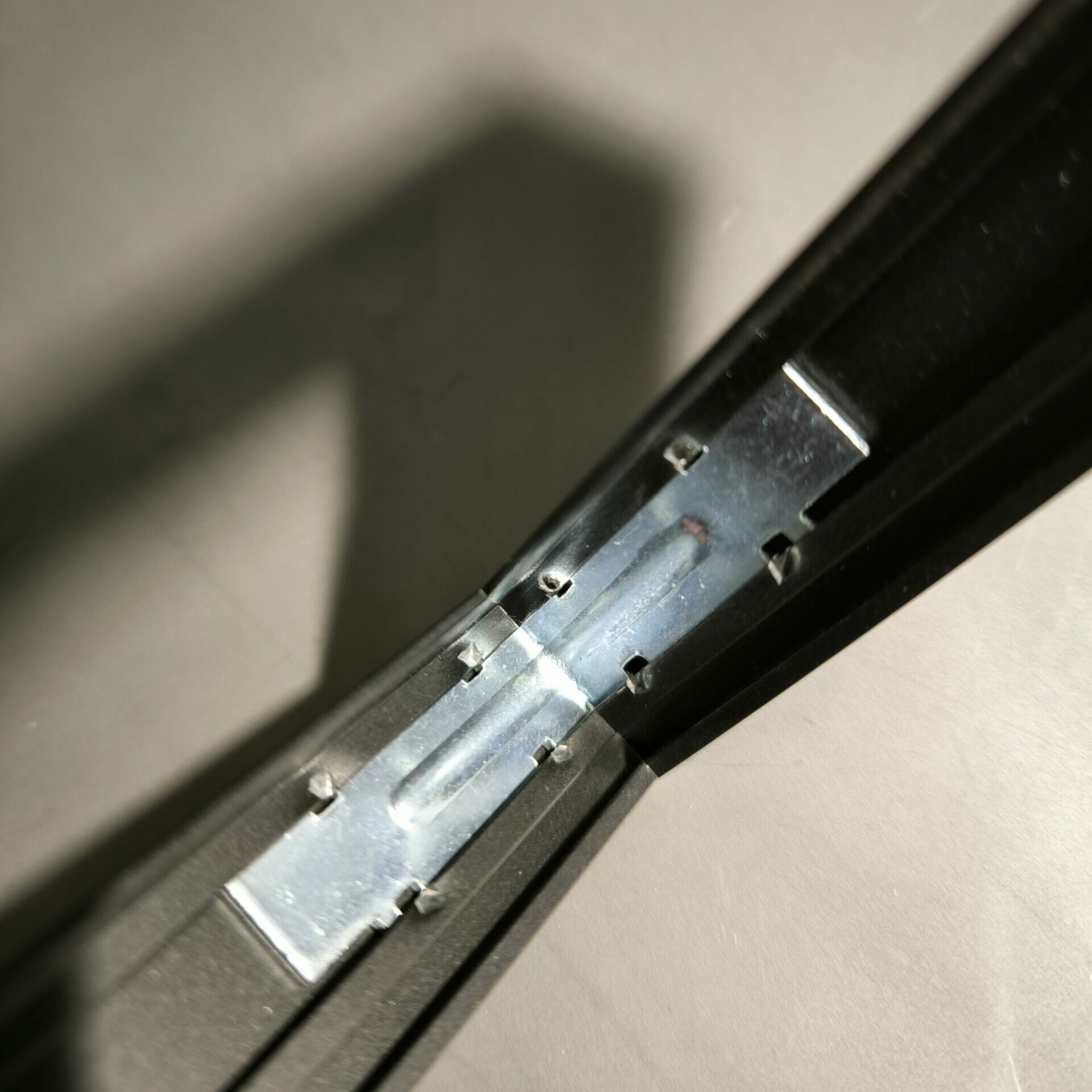

For a manufacturing client, Fabrit designed and delivered a new corner crimping machine for aluminum frames, intended to ensure strong and precise joining of profile corners.

The objective of the project was to replace a worn-out machine with a modern, reliable solution capable of generating sufficient clamping force while offering greater production flexibility.